-

Alloy Steel vs Stainless Steel: Which Is Better for Your Project?

Alloy Steel vs Stainless Steel: Which Is Better for Your Project?

Choosing the right type of steel directly impacts the success of your project, whether you’re constructing a building, designing machinery, or sourcing materials for fabrication. Alloy steel and stainless steel are two popular options, each with specific benefits and applications. Understanding their differences can help you make informed decisions that meet your project’s exact requirements. Below, we’ll compare these two metals, their types, and the factors to consider when selecting the ideal solution for your project.

What Are Alloy Steel and Stainless Steel?

Both alloy steel and stainless steel belong to the larger family of steel but differ in composition and properties.

- Alloy Steel is carbon steel mixed with additional elements like manganese, nickel, chromium, and molybdenum. These additions enhance its strength, toughness, and resistance to wear and fatigue. It is commonly used for heavy-duty applications like pipelines, machinery parts, and automotive components.

- Stainless Steel is steel that contains at least 10.5% chromium, giving it excellent corrosion resistance. Used in environments prone to moisture or chemicals, stainless steel is ideal for food processing, medical devices, and construction.

Understanding the basics of each type can guide your selection and guarantee the material meets your engineering or industrial needs. Discover the rich history and unparalleled expertise of McKnight Steel.

Why It’s Important to Choose the Right Steel

The success and safety of your project heavily relies on selecting the right material for specific applications. Choosing incorrectly can lead to material failure, reduced performance, or higher costs. Here are some key points to consider:

- Project requirements may demand specific grades or tolerances of steel.

- Environmental conditions, such as exposure to moisture or extreme temperatures, should guide material choice.

- Performance, including strength or resistance to corrosion, depends largely on steel type.

At McKnight Steel & Tube Co., we understand these needs and stock a broad range of alloy and stainless steel to help meet your exact specifications. With fast delivery times across Warminster and Philadelphia, our team keeps your project on schedule.

Explore our extensive inventory to help you plan for your next project with ease.

Types of Steel to Know About

Both alloy steel and stainless steel come in different forms designed for specific purposes.

Types of Alloy Steel

- High-Strength Low-Alloy Steel (HSLA): Ideal for structural applications due to its strength and lightweight properties.

- Tool Steel: Used for cutting, shaping, and drilling due to its hardness and wear resistance.

Types of Stainless Steel

- Austenitic Stainless Steel: Non-magnetic and resistant to corrosion. Austenitic stainless steel is widely used in many industries and applications.

- Ferritic Stainless Steel: Magnetic and less corrosion-resistant but cost-effective for automotive parts. It offers excellent ductility and formability.

- Martensitic Stainless Steel: Strong and hard but less corrosion-resistant and more difficult to fabricate. Used where hardness is required.

Understanding the range of steel types available allows you to select one aligned with your functional and environmental requirements.

Comparing Key Factors

To help make your decision, here’s a quick comparison of alloy steel and stainless steel based on important criteria.

- Corrosion Resistance: Stainless steel is generally better suited for environments prone to moisture or exposure to chemicals.

- Strength: Alloy steel, especially tool steel or high-strength low-alloy steel, offers superior strength and wear resistance.

- Cost Efficiency: Alloy steel tends to be more economical, especially for large-scale projects where corrosion resistance isn’t a priority.

Each material excels in certain areas, so selecting the right steel depends on its intended application.

Why Choose McKnight Steel?

At McKnight Steel & Tube Co., we’ve been serving the Philadelphia and Warminster, PA, areas since 1954. Here’s why engineers, metal purchasers, and construction companies trust us:

- Extensive Inventory: Stocking carbon, stainless, aluminum, and alloy tubing and pipe in various shapes (round, square, and rectangular).

- Fast Delivery: Our company trucks deliver within a 120-mile radius of Warminster, PA, with quick turnaround times.

- Value-Added Services: Cutting to precise lengths, deburring, threading, and fabricating.

- One-Stop Solution: Customers can order both tubing and complementary metal shapes, such as angles and channels, ensuring their entire project’s needs are met.

With an unmatched commitment to service and reliability, McKnight Steel provides materials that meet your project specifications and delivery schedules.

Contact Us for Your Steel Needs

Selecting the right steel doesn’t have to be complicated. With expertise spanning over six decades, McKnight Steel & Tube Co. is ready to help find the perfect material for your project. When you need alloy steel for its strength or stainless steel for its durability, we stock a vast inventory to meet your needs.

Contact us today at 215-396-9976 to request a quote or speak with our experienced team. Family-owned and operated since 1954, we are here to ensure your project’s success—on time, every time.

-

What Are Different Types of Steel?

What Are the Different Types of Steel?

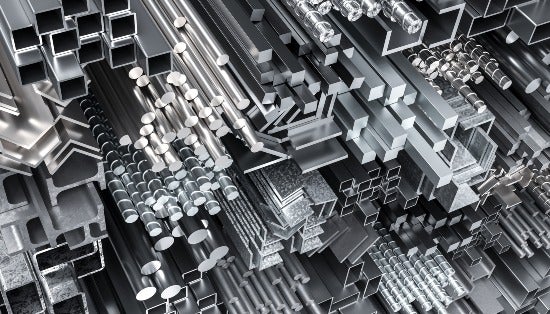

Steel is one of the most versatile and extensively used materials in the world. Its combination of strength, durability, and adaptability makes it an integral part of countless industries, from construction to manufacturing. For businesses, understanding the different types of steel is key for sourcing the right material for projects. Explore the types of steel, their characteristics, and practical applications to help with informed decisions.

What Is Steel?

Steel is an alloy primarily composed of iron, combined with varying amounts of carbon and other elements, such as manganese, chromium, nickel, or vanadium. The carbon content, typically between 0.2% and 2.1%, provides the steel’s hardness and strength. By adjusting the composition, various types of steel are created, each designed for different applications.

Steel’s popularity stems from its high strength-to-weight ratio, its versatility, and its ability to be recycled. When you need material for machinery, infrastructure, or decorative elements, steel offers scalable options. For more details on steel options and our supply services, visit our products and services page.

Types of Steel

Steel is broadly categorized into four main types, each suited for specific uses:

1. Carbon Steel

- Composition: Primarily iron and carbon, with minor traces of other elements.

- Grades

- Low Carbon Steel (mild steel): Easy to machine and weld. Used for structural elements and car parts.

- Medium Carbon Steel: Greater strength and wear resistance, making it ideal for automotive components and tools.

- High Carbon Steel: Extremely hard and durable, often used in cutting tools and springs.

- Applications

- Construction (beams, columns, girders)

- Machine parts

- Automotive components

- Tools and knives

2. Alloy Steel

- Composition: Mixed with elements like chromium, nickel, and molybdenum.

- Purpose: Enhances properties like strength, toughness, and corrosion resistance.

- Applications:

- Pipelines

- Gears

- Automotive parts

- Turbine blades

Alloy steels vary greatly in strength and performance based on their composition.

3. Stainless Steel

- Composition: Contains at least 10.5% chromium, which creates a corrosion-resistant surface.

- Key Features:

- Rust and stain resistance

- Aesthetic appeal

- Applications:

- Kitchen equipment

- Medical instruments

- Architectural facades

- Automotive trim

At McKnight Steel, our stocking capabilities ensure we provide premium stainless steel materials suitable for an array of demanding projects. Learn more about why we stand out as a steel supply company.

4. Tool Steel

- Composition: High carbon content with additional alloys to enhance hardness and heat resistance.

- Applications:

- Cutting tools

- Dies and molds

- Drill bits

Tool steel is specifically engineered for industrial applications requiring extreme durability.

Specialty Steels

Specialty steels are high-performance materials developed for specific applications. Examples include:

- High Strength Low Alloy (HSLA) Steel: Lightweight and strong, used in automotive frames and bridges.

- Weathering Steel (such as COR-TEN): Resistant to atmospheric corrosion, making it ideal for outdoor structures.

Choosing the Right Type of Steel

Selecting the appropriate steel type will determine the success of your project. Below are factors to consider:

- Application: What is the end use? Structural components, tools, or decorative items may require different steel types.

- Environment: Will the steel be exposed to moisture, chemicals, or extreme temperatures? Opt for corrosion-resistant alloys as needed.

- Specifications: Refer to engineering drawings and industry standards (e.g., ASTM, SAE) to support compliance.

- Budget: Choose steels that balance performance requirements with cost efficiency.

If you’re unsure about the best options for your business, our team of experts can help guide you.

Why Choose McKnight Steel?

Since 1954, McKnight Steel & Tube Co. has earned a stellar reputation in Warminster and Philadelphia as a reliable, family-operated steel supplier. Here’s what sets us apart:

- Extensive Inventory: Carbon, stainless, aluminum, and alloy tubing and pipe products in various shapes and sizes are readily available.

- Fast Delivery: We strive for 24-48 hour turnaround times on stock items with no extra shipping charges for deliveries within a 120-mile radius.

- Stocking Distributor: Unlike competitors, we maintain an inventory, ensuring quicker and more reliable order fulfillment.

- Whole-Order Fulfillment: Need tubing and additional metal components like angles or channels? We provide everything you need for your project.

- Customer Focus

- Material cut-to-length and deburring services as needed.

- Assistance from knowledgeable industry professionals.

To learn more about what makes us the preferred regional metal supplier, check our services page.

Start Your Order Today

Steel is an essential material for many industries, and McKnight Steel is here to provide high-quality, reliable solutions for your needs. Whether you’re an engineer looking for a specific grade or a metal purchaser sourcing bulk inventory, we have you covered.

Contact us today to discuss your requirements or request a quote. Call us at 215-396-9976 or visit our contact page to get started. With decades of expertise and a customer-first commitment, we’re ready to deliver the materials your project demands—on time and to specification.

-

Why Choose Us?

When it comes to sourcing steel tubing, pipe, or other metal products, contact McKnight Steel for a quote. At McKnight Steel, we dedicate ourselves to being your partner in every project. We’re committed to quality, customer service, on-time delivery, and competitive pricing on our diverse range of products. Make McKnight Steel your go-to supplier for your tubing, pipe, and metal product needs.

Metals Industry Experts

Established in Philadelphia in 1954, McKnight Steel & Tube Co. has 70 years of experience in the metals industry. Our expertise spans a wide variety of metal products, ensuring that we meet all our customers’ standards and specifications. McKnight Steel also offers value-added services like precision cutting and deburring, and we work with other businesses to fulfill additional processing and fabrication needs.

A Rich History and Strong Community Ties

McKnight Steel has built a reputation for reliability and superior service. Our success and growth over several decades prompted a strategic move to Ivyland, a borough in Warminster, PA, in 1993. The legacy of our family-owned and operated metal service center is defined by the relationships we’ve built over the years. Looking back, we take pride in the enduring values that continue to shape McKnight Steel to this day.

As a regional wholesale distributor of metal products, our current service areas include Pennsylvania, New Jersey, Delaware, Maryland, and Virginia. We also serve customers throughout the United States with exceptional metals industry knowledge and a focus on customer satisfaction.

Diverse Product Offerings

Our inventory includes an extensive selection of metal products, including carbon, stainless, aluminum, and alloy tubing and pipe, as well as other metal shapes like angles, channels, bars, rods, beams, and plates. We supply ASTM, SAE, and DFAR-compliant materials and provide Material Test Reports and Certificates of Conformance upon request.

We supply both industry-standard and specialty size material, available in imperial and metric measurements. From sourcing difficult-to-find products to providing valuable insight into material availability, we’re equipped to meet your project’s unique requirements.

The Advantage of a Local Metals Distributor

As a stocking distributor based in the Philadelphia, PA area, we offer competitive pricing and maintain quick turnaround times on all quotes, orders, and deliveries. We also offer stock-and-release programs, with material ready to move within 24 to 48 hours. Our delivery options are flexible, utilizing company trucks to deliver within a 120-mile radius of Philadelphia and common carriers to deliver across the United States.

We cater to a wide array of businesses, from machine shops and construction companies to metal fabricators and distributors. Our goal is to exceed expectations and create lasting relationships with our customers. We’re always ready to offer suggestions and recommendations for any application involving metal products.

High-Performance Cutting Applications

Our Hydmech H-18A and S-23A saws are equipped with advanced hydraulics and powerful motors to deliver clean, accurate cuts. These saws can handle a wide range of materials and sizes reliably and cost-effectively.

Our Promise to You

With seven decades in the industry, our success has hinged on meeting specifications, timely shipping quality products, and customer service. We pride ourselves on having a knowledgeable and professional staff ready to anticipate and meet your needs.

Frank McKnight, the owner of McKnight Steel & Tube Co., would like to thank our customers and the metalworking community for their trust and support over the years. We promise to maintain high standards to help those in the metalworking and manufacturing sectors overcome even the most challenging projects.

For all your metal needs, please contact us today at (215) 396-9976 or email sales@mcknightsteel.com. We look forward to contributing to your project’s success.

-

McKnight Steel: Your Trusted Local Metal Tubing Supplier

When it comes to sourcing metal tubing, quality and reliability are important. If you are seeking a dependable local supplier in the metal tubing industry, try McKnight Steel. With a commitment to excellence, a rich history, and products meeting ASTM specifications, McKnight Steel has established itself as a top choice for metal tubing needs.

A Legacy of Excellence

McKnight Steel, a family-owned business with decades of experience, has a legacy of excellence that extends back to its founding. Established in 1954, McKnight Steel has become an integral part of the local community, providing metal tubing and related products to a diverse range of industries. Over the years, the company has built a reputation for consistently delivering quality products meeting customer specifications.

Diverse Product Range

McKnight Steel’s commitment to quality extends across a diverse range of metal products. Whether you’re in the automotive, construction, fabrication, manufacturing or other industry, McKnight Steel has tubing products that meet your needs. Material is available to ASTM specifications with accompanying material test reports. Product offerings include:

- Round Tubing: From standard sizes to custom orders, McKnight Steel offers round tubing in dimensions for a variety of applications.

- Square and Rectangular Tubing: Perfect for structural applications, square and rectangular tubing are known for strength and versatility.

- Mechanical Tubing: Designed for a wide range of mechanical applications, this tubing is ideal for those seeking reliability and durability.

- Stainless Steel Tubing: When corrosion resistance is essential, McKnight Steel provides a range of stainless steel tubing options.

- Aluminum Tubing: For lightweight yet robust solutions, aluminum tubing is sought after in industries where weight is a critical factor.

Unmatched Customer Service

McKnight Steel works to provide exceptional customer service. Our experienced team is ready to assist you in choosing the right tubing for your specific application, offering technical expertise and guidance through the process. Whether you have questions about ASTM specifications or need assistance with a custom order, we are here to support you.

McKnight Steel’s success is in its customer-centric approach. We view each customer as a valued partner and strive to build lasting relationships based on trust and mutual success. This approach is reflected in several key aspects of our operations:

- Competitive Pricing: McKnight Steel maintains competitive pricing, ensuring that customers receive excellent value for their investment.

- On-Time Delivery: Recognizing the importance of timeliness, McKnight Steel is committed to delivering orders on schedule so customers meet project deadlines.

- Responsive Customer Support: McKnight Steel’s sales team is readily available to assist with inquiries, orders, and technical assistance. They prioritize responsiveness and aim to provide solutions promptly.

Conclusion

McKnight Steel & Tube Co. works to serve its community as a quality local metal tubing supplier. With a legacy of excellence, a commitment to quality, and a diverse range of in-stock tubing products, McKnight Steel works to earn the trust of its customers. When you choose McKnight Steel as your metal tubing supplier, you’re not just getting a metal product; you’re gaining a partner dedicated to your success.

-

McKnight Steel: Your Top Choice for Tubing and Pipe

When it comes to sourcing tubing and pipes, finding a reputable supplier is paramount. Among the industry players, McKnight Steel stands out as a trusted name in providing top-notch products and exceptional customer service. With a rich history and commitment to excellence, McKnight Steel has established itself as the go-to-choice for businesses and individuals alike.

History and Expertise:

McKnight Steel boasts a long-standing history in the steel industry. Established in 1954, the company has accumulated a wealth of experience and expertise in metal tubing and pipe distribution. With a solid foundation, McKnight Steel is a reliable partner for all your tubing and pipe needs.

Extensive Product Range:

McKnight Steel maintains an extensive product range. The company offers a vast selection of tubing and pipes, catering to diverse applications and industries. Whether you require carbon steel, stainless steel, alloy, or specialty metals, McKnight Steel has you covered. From standard sizes to custom specifications, McKnight Steel can provide the right tubing and pipes to suit your specific requirements.

Uncompromising Quality:

Quality is of utmost importance when it comes to tubing and pipes, as they often serve critical functions in various applications. McKnight Steel understands this and is committed to delivering quality products with material test reports. When you source tubing and pipes from McKnight Steel, you can rest assured that you are receiving a reliable, durable, and top-performing product.

Cut-to-Length:

Every project has unique requirements, and McKnight Steel understands the importance of having material cut to the necessary lengths. McKnight Steel offers comprehensive cut-to-length options, allowing you to tailor tubing and pipes to your needs. This level of customization ensures that you receive products that seamlessly integrate into your project, saving time and expense.

Timely Delivery:

Meeting project deadlines is crucial, and delays in material delivery can disrupt schedules and cause setbacks. McKnight Steel prides itself on its efficient logistics and prompt delivery services. With a well-established supply chain network and streamlined processes, McKnight Steel ensures that your tubing and pipes reach you on time.

Customer-Centric Approach:

At McKnight Steel, customer satisfaction is key. McKnight Steel’s dedicated team of professionals provides exceptional customer service, offering guidance, technical expertise, and prompt responses to queries. Whether you have questions about product selection, specifications, or any other concerns, the sales team is ready to assist you. With a customer-centric approach, McKnight Steel builds long-term relationships and strives to exceed customer expectations.

Give Us a Try and Choose McKnight Steel:

When it comes to sourcing tubing and pipes, McKnight Steel emerges as a clear choice. With its history, extensive product range, commitment to quality, cut-to-length options, reliable delivery, and customer-centric approach, McKnight Steel has a reputation as a trusted metal supplier. Whether you are involved in machining, metal fabricating, mechanical contracting, metal distribution, equipment manufacturing, construction, the motor sport industry, or any other industry requiring metal tubing and pipes, contact McKnight Steel for a no obligation quote on your tubing and pipe needs.